The Vibromatic Team is here to design and build your next part handling system.

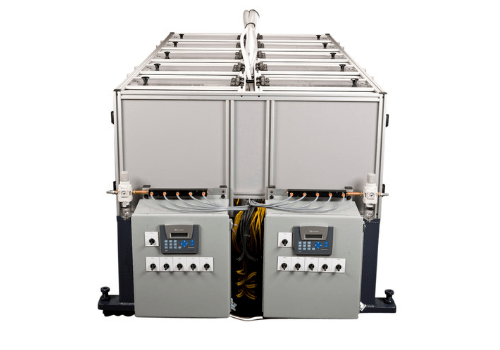

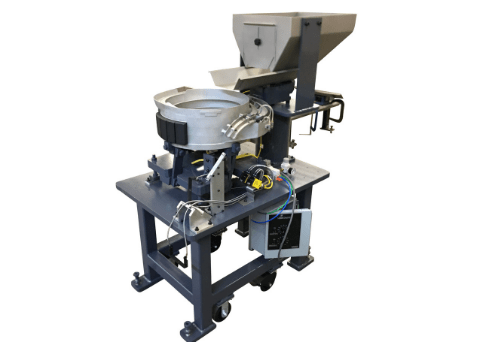

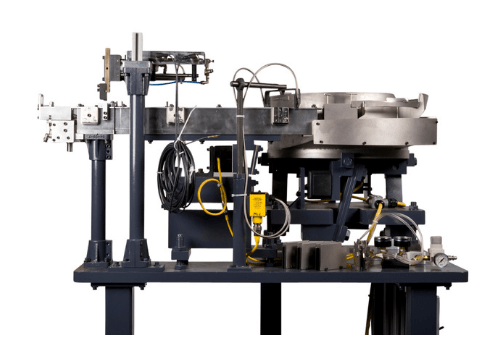

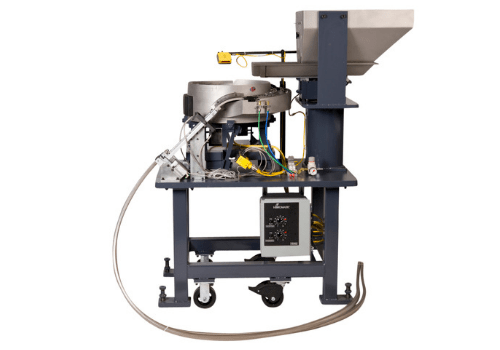

Vibromatic will work with you from preliminary concept through build, design and production startup. Your vibratory feeder bowl or part handling system will be custom built to your satisfaction. All Vibromatic Part Handling Systems are built around a parts feeder, using a building block approach by adding as many components as you desire. Components such as vibratory hopper pre-feeders, centrifugal feeders, vibratory drive units, vibratory tracks, parts sorters and part escapement and placements can be added as options. Vibromatic can take your parts from bulk to placing them onto your tooling. In addition to this, Vibromatic also designs and builds two-part sub-assembly stations.

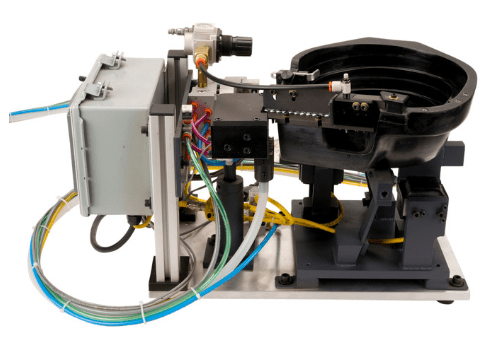

Part Handling Systems, vibratory, centrifugal, floor, and stepper feeders are custom designed and manufactured by Vibromatic. Since 1956, Vibromatic has been the leader in producing the finest Vibratory Parts Feeding and Part Handling Systems on the market. Today, this same drive and dedication to excellence bring custom tooled centrifugal feeders and Centrifugal Orbital Mechanical Parts Feeder System (OMS) to fit your part handling systems needs. Our custom vibratory and mechanical bowl feeders are designed specifically to convey your parts to Vibromatic custom built Gravity Tracks, Air or Belt Conveyors, Vibrating Tracks, Escapement and Placement Mechanisms.

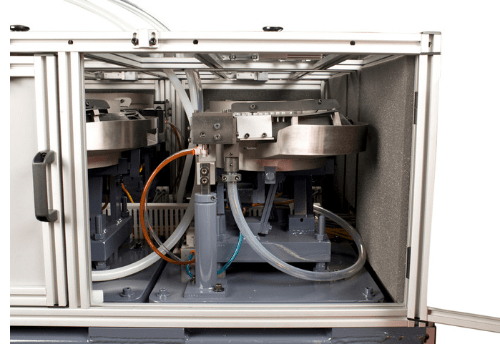

Vibromatic’s engineers and CAD designer’s dedication and innovation resulted in the development of our Centrifugal OMS Part Handling and Feeding System. During the design and development stages of this unique parts feeding device, we kept one very important goal in mind: it must be fast and it must be accurate. This goal was achieved thanks to the creation of our patented “Star Wheel” technology that assures 100% orientation of metal caps and closures at speeds of up to 3,000 parts per minute. Rounding out the advantages of our Centrifugal OMS Parts Feeding and Handling System is its compact size that minimizes work site requirements.

Since 1956 Vibromatic has accumulated a history of successful parts handling experience. Our knowledge and experience accumulated over these years was incorporated into the collateral design features of the Centrifugal OMS Part Handling and Feeding system. One of the many unique features of our OMS Systems includes prevention of part contamination.

This is accomplished by assuring that all tooling which comes in contact with your parts is constructed of durable 300 Series stainless steel or polymer material which prolongs production life and lowers contamination possibilities. A Lexan” hinged lid also prevents parts and equipment from exterior contamination. Durable stainless steel tracks are custom designed to convey your parts efficiently to meet your application and space requirements. For ease of maintenance and reliability, the fiber optic device of our OMS parts feeding system features a removable top cap which also prevents lens and fiber optic contamination. Put the experience of Vibromatic to work for you today.

When speed and accuracy are critical Vibromatic knows that the key to your success is not just speed, but accurate speed. Engineered for performance, Vibromatic’s line of Centrifugal Orbital Mechanical Part Handling and Feeding Systems (OMS) can deliver cylindrical parts at rates of up to 3,000 parts per minute with 100% orientation. That’s the kind of results built into every Vibromatic OMS parts feeding system.

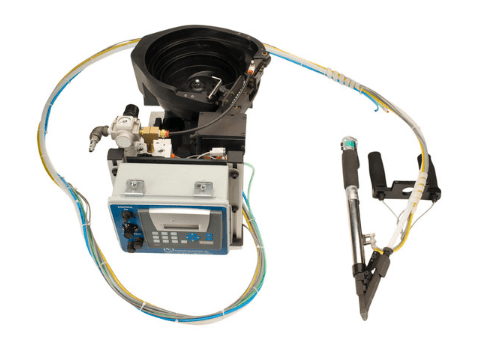

Vibromatic also provides a complete line of vibratory automatic parts feeding systems including vibratory feeder bowls, vibratory parts sorters, parts feeder bowls. We also offer optional support components such as vibratory feeder bowl drive units, vibratory tracks tooled to convey your part from either a vibratory or centrifugal parts feeder, orienting rolls, feeder bowl controls, bulk hopper to meter your parts into a vibratory or centrifugal parts feeder, floor or linear parts feeders, sound enclosures to lower the sound level of the vibratory or centrifugal feeder bowl.

Vibromatic also provides single station assemble mechanisms and automatic screwdrivers that assemble parts tracked from vibratory and centrifugal parts feeders or we can provide just the escapement portion thus allowing the user to design his own placement or assembly mechanism.