Automotive

Since 1956 Vibromatic has designed and built state of the art custom parts feeding systems for the Automotive Industry. As the parts handling leader Vibromatic has continued to use the latest technologies available and develop new products to remain a leader in our field. We are always focused on continuous innovation, quality products, and building strong partnerships with our customers.

Automotive companies were some of the first to embrace parts feeding systems on assembly lines. They quickly found that by installing a Vibromatic parts feeder system on the assembly line it would greatly increase productivity, reliability and profitability.

Throughout the decades we have fed thousands of parts for all of the major automotive manufacturers from small parts for a truck to precision parts for electric cars. The parts could be as challenging as lightbulb filaments or fuel injector components, trim clips, filters, spark plugs whatever the part or challenge you have, contact one of our Application Engineers today.

Consumer

It’s highly likely that you have you used a consumer good today that has had components that was fed from a Vibromatic parts feeder system. It could have been the cap from your shampoo, the razor handle from your shave this morning to the milk cap or laundry detergent cap the list goes on as most of the products we use today are being produced on highly automated assembly lines. These modern assembly lines require high feed rates along with high reliability this is why many of the consumer good companies use Vibromatic Company as there parts feeding partner. Since 1956 Vibromatic has been a leader in designing and building state of the art custom parts feeding systems and building strong partnerships. Put us to work for you today by contacting one of Vibromatic’s highly experienced Application Engineers today with your project requirements.

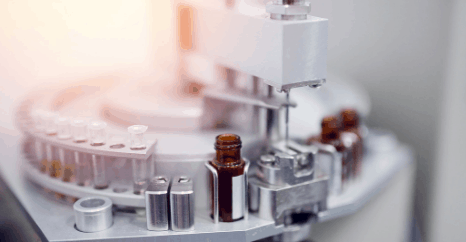

Medical/Pharmaceutical

Vibromatic Bowl feeder systems built for the medical and pharmaceutical industries are held to very strict specifications with many of these industry standards being developed by Vibromatic over the years. The requirements involved in the production of these types of products must be built to precise and clean specifications along with detailed documentation. Special metals and unique methods are used in building a Vibromatic Feeder Systems which require a great deal of craftsmanship and attention to detail. Vibromatic uses it’s 63 plus years of experience along with our expert craftsmen to incorporate all the requirements in each of our custom tooled parts handling systems. Call or email an experienced Vibromatic Application Engineer today with your project requirements.

Packaging

Vibromatic has a long history working within the packaging industry and pushing the limits and using cutting edge technologies to exceed our customers’ expectations. We have researched and developed many different and unique parts feeding systems to meet the needs of an ever changing and fast paced automated packaging industries. We have developed and patented a small centrifugal feeder system that can feed 28mm caps at rates of over 3000 parts a minute with 100% orientation.

We have also provided feeder systems to feed and orient fragile glass parts for inspection and filling line at high rates and no damage to the parts being fed. From scoops, caps, lids, medical devices, high feed rates to delicate parts we will work with you to solve your parts handling issues and keep your assembly lines flowing without issue. We love a challenge and want to earn your business and become your partner in productivity. Whatever the part or challenge you have, contact one of our Application Engineers today.

Cosmetic

Just like the high-quality cosmetic products that manufacturers make and proudly display they expect that the parts feeding system will gently handle their parts without marring, scuffing or scratching. Vibromatic has worked with the cosmetic industry for many decades to help develop many of the feeding solutions and standards that are required in today’s cosmetic manufacturing industry. Vibromatic understands this and will design a custom solution that will meet your needs and help get your product to market so that the integrity of your product shines above your competition. Call or email a Vibromatic Application Engineer to inquire about how one of our proven engineered or custom design solutions can work for you. Vibromatic wants to be your partner in productivity.

Electronics

A wide range of products fall in this ever-changing industry. Just like the electronics industry Vibromatic has continually evolved and changed to keep pace since 1956. Some of the first jobs we built parts handing systems for was a major phone manufacturer that was also one of the largest in the world. To keep up with production they were aware very early that they could produce a better quality phone in larger numbers by using Vibromatic parts handing systems in place of machine operators. Vibromatic fed many of the electrical components in a phone including the audio receiver and microphone that went into the handle of a phone.

Just like the evolution of phones and the electronic industry, Vibromatic has embraced the automation revolution and has evolved and developed new technologies and processes that are currently being used on modern assembly lines. Name a major electronics manufacturer and we have probably built a feeder system for them. So if you need to feed coaxial cable connectors, Ethernet plugs to connectors Vibromatic has a solution. It can be a vibratory feeder, centrifugal feeder, Step Feeder, Polycast™ Bowl or even a Vibromatic Flex-Feeder. Whatever the part or challenge you have, contact one of our Application Engineers today to see how we can help you with an engineered solution.

Manufacturing

Since 1956 Vibromatic has designed and built state of the art custom parts feeding systems for manufacturers in the United States as well as the rest of the automated world. Today almost all massed produced parts or products are manufactured on assembly lines with fewer operators and more automated stations with parts handling systems. As the parts handling leader Vibromatic has continued to use the latest technologies available and develop new products to remain a leader in our field. We are always focused on continuous innovation, quality products, and building strong partnerships with our manufacturing customers.

Throughout the decades Vibromatic has fed thousands of parts for all types of major manufacturers in the world. From small parts used in electric cars, the key fob you used today, the shampoo cap you opened this morning, the razor, toothbrush, the refrigerator you opened, to the cap used on the milk container these are some of the mass-produced items that use a Vibromatic Parts handling system to supply the assembly lines. Vibromatic was one of the pioneers in this field and continues to innovate for the future needs of the growing fast paced world. Whatever the part or challenge you have, contact one of our Application Engineers today to see how we can help you with an engineered solution.

Fasteners

A wide range of products fall into the fasteners industry. Vibromatic has continually evolved and changed to keep pace since 1956. We have developed a full line of off the shelf type of feeder systems for faster delivery and at less cost than a traditional stainless steel feeder bowl. This line is known as the Polycast™ line of feeder systems. These patented feeders are cast from special blends of polyurethane which produce a feeder that can be manufactured quickly, long production life and feed a large family of parts with the optional tooling packages. Bowl sizes range from 7” up to 18” in both a CW and a CCW rotation.

We know that one size does not fil all so we also that is why we offer complete part handling systems. It can be a vibratory feeder, centrifugal feeder, Step Feeder, Polycast™ Bowl or even a Vibromatic Flex-Feeder. Whatever type of fastener you need to feed or the challenge you are facing, contact one of our Application Engineers today to see how we can help you with an engineered

solution to your part handling problem.