Floor feeders, stepper parts feeders, and step feeders are custom-designed to handle your parts reliably even if they are covered with oil or other harsh substances.

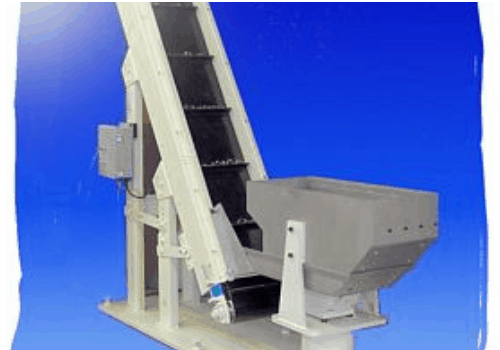

They are also capable of handling large parts at higher rates than can be achieved in most vibratory bowl feeders. The elevator of our Vibromatic floor parts feeder can be either belt or stepper type depending upon which is best to suit your needs. Our models FBF and FSF are available in five standard sizes ranging from one to ten cubic foot storage capacity with lower load heights than vibratory part handling systems.

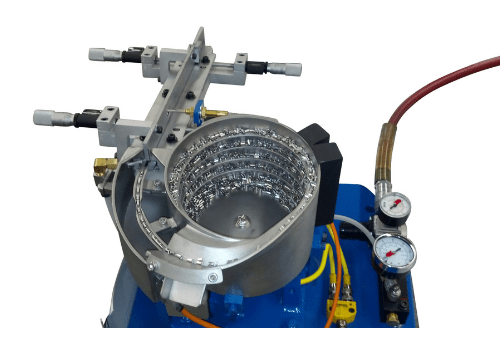

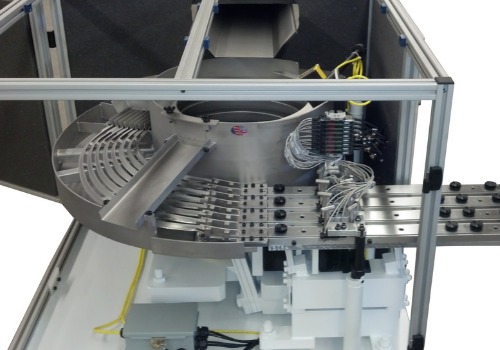

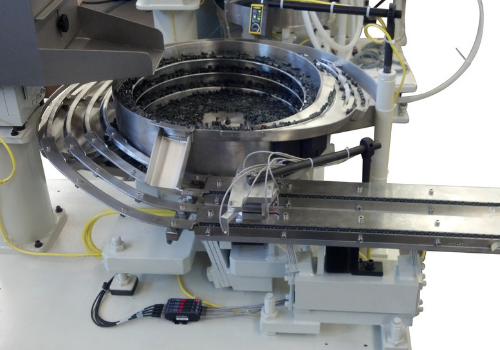

Vibromatic offers a complete line of stepper feeders and turnkey part handling systems including vibratory, linear and centrifugal feeders designed and manufactured to fit your part handling system needs. Our custom stepper and floor parts feeders are designed specifically to convey your parts to custom-built gravity tracks, air conveyors, belt or vibratory conveyors, vibrating tracks, escapement and placement mechanisms.

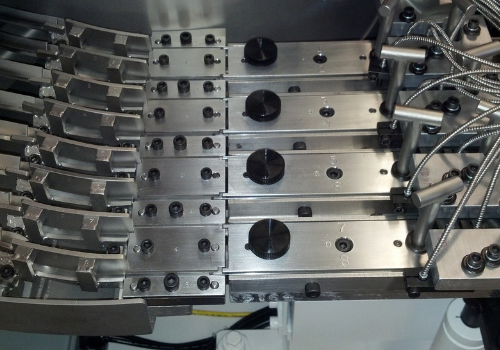

Stepper and floor feeders are offered by Vibromatic with one goal in mind: they must be fast and they must be reliable. This goal is obtained thanks to year of innovation in the parts handling industry. Vibromatic offers years of parts handling experience incorporated into the collateral design features of Stepper and Floor Feeding systems. All tooling that comes in contact with your parts is made of durable 300 Series stainless steel or heat-treated material to prolong equipment life and lower contamination possibilities. Durable stainless steel air or belt tracks, are custom designed and fabricated to accept your parts from our unique centrifugal feeder systems that will fit your application and space requirements. Put the experience of Vibromatic to work for you today. When speed and accuracy are critical, the key to your success is not just speed, but accurate speed.