Case Setting:

A construction equipment manufacturer needed a flexible feeding solution for a large family of large heavy castings. The castings ranged from a few ounces up to a few pounds and many different geometric shapes.

The objective was to build a heavy duty flexible feeding system so that the entire family of parts can be fed and 100% inspected prior to assembly. This customer was not very automated at the time and had concerns this could be done and was considering sending the operation

Result:

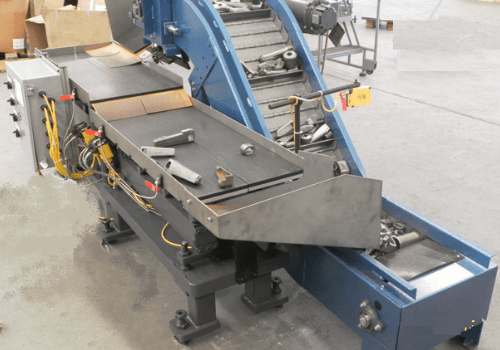

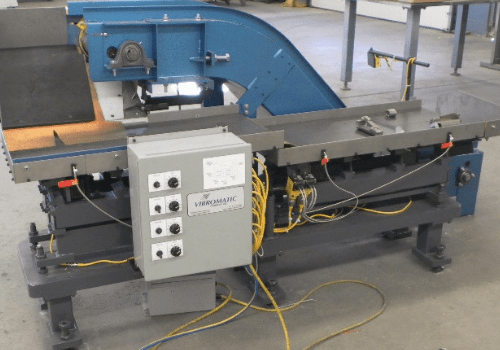

After discussions with the Vibromatic team, a solution soon followed. The solution was to make a heavy duty steel cleated “S” conveyor that would bring a few of the parts from the bulk hopper up and onto the first inline vibratory separator tray.

The vibration of this tray was controlled by a Vibromatic H series controller and was set at a faster speed to separate the parts and feed onto the second vibratory tray. This vibratory tray was used as the pick area for the vision-guided robot and also used a Vibromatic H series controller but ran slower and the tray used a wide photo beam to ensure parts were available for the robot to pick. After the robot picked the parts, the tray would vibrate and repopulate the pick area with fresh parts for the robot to pick. Any of the parts not picked by the robot would be turned to the conveyor to start over again.

This system proved to be very successful and we have used variations of this system for many other parts and customers. Interested in a system like this or another application? Contact us at sales@vibromatic.net for additional information.