Case Setting:

The customer had previously purchased a 2-line feed system to feed a Plug end to end at random down a dual-line tooled vibratory SL track and into the customer’s nest.

Problems push or back pressure in the tracks caused problems loading parts into each of the (2) machine nests; improper-load &/or failure to load the parts every machine cycle. We discussed with our customer and did a feasibility study to see if we could provide a different design method for a new design feed system to replace the above system which failed to perform as needed and without the faults/problems experienced with the existing system.

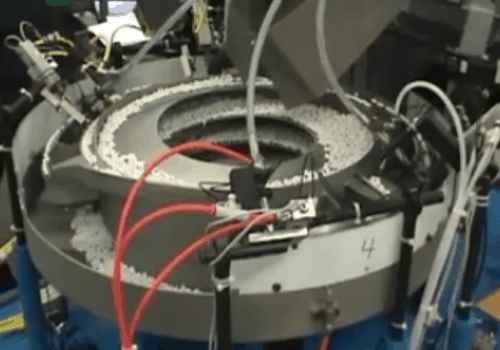

Following the feasibility study, we provided a new replacement 4-station feed system which orients that parts standing, axis vertical, isolating a single-part in each of the 4-lines. Each line has an independent escape & blow mechanism to blow one part at a time, end-to-end through flex-tubing and to the machine isolated part nest. Production running this system provides a total of 120 parts per minute.

Result:

Customer installed the system on their machine, it is and has performed to specifications for 2+ years.