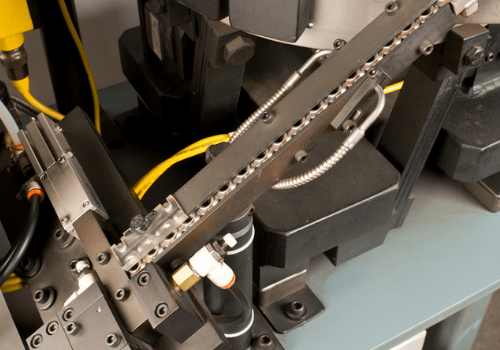

Tracking via vibratory straight line track is our most popular option.

A workhorse designed to provide efficient part storage and transport in a very cost-effective manner. The vibratory straight line drive units we use to provide power for these tracks work on exactly the same principle as our vibratory parts feeder bowls.

Air Tracks

Vibromatic air conveyor track systems convey oriented parts with momentum from air jets in a stainless steel deck. In addition to providing transportation, the system provides accumulation without product jamming or damage. These tracks can use compressed air or air from motor driven fans.

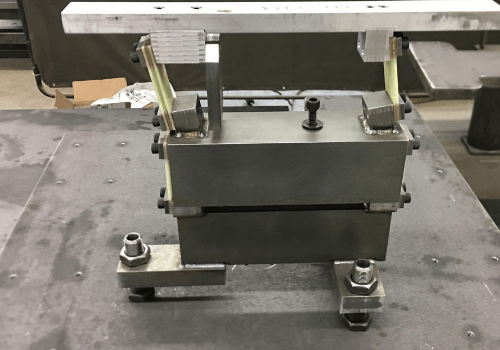

Conveyor Belt Tracks

Vibromatic Custom Conveyor Tracks are motor driven and designed to move parts gently with or without confinement. They can accommodate a longer overhang than a vibratory inline track to deliver parts into your machine station as required. They can be geared to your specified fixed linear inch per minute travel speed or designed with as a variable speed configuration. Conveyor tracks are much quieter than vibratory tracks and come in many different sizes and configurations to meet you specific application. Some examples are flat belt, round belt and textured.

Vibromatic Custom Conveyor Tracks are utilized by all industries including, pharmaceutical, automotive, electronic, cosmetic, food, packaging, plastics, glass, foundry, steel, construction, and metalworking industries. Vibromatic custom parts handling systems offer a cost-effective alternative to manual labor, saving manufacturer’s time and labor costs. Several factors must be considered when selecting the best parts handling system for your application. Contact a Vibromatic engineer today to discuss your application and put our experience and expertise to work for you.

Gravity Tracks

In certain applications, belt tracks, air conveyor tracks, or airveyor tracks might make a more attractive option. Parts are carried from the vibratory parts feeder bowl, centrifugal feeder bowl, stepper feeder, or linear part feeder, to the machine by the action of a belt conveyor track or air conveyor, eliminating the noise inherent in the vibration of a regular vibratory straight line track. (If vibratory tracking is designed into your parts feeding package, optional sound enclosures are available to reduce the noise level). This provides a very positive and reliable method to transfer specific families of parts from vibratory parts feeder bowls, centrifugal feeder bowls, stepper feeders, or linear parts feeders to your assembly or work stations.

We also provide “orienting roll” tracking to handle parts with very little dimensional differences. This design allows us to detect minute differences that are too critical to detect in an automatic vibratory feeder bowl, when sorting headed, round, tapered, cylindrical or other similar parts. It is also a very effective method to inspection and sort your parts accurately. Request a quote today to learn more.