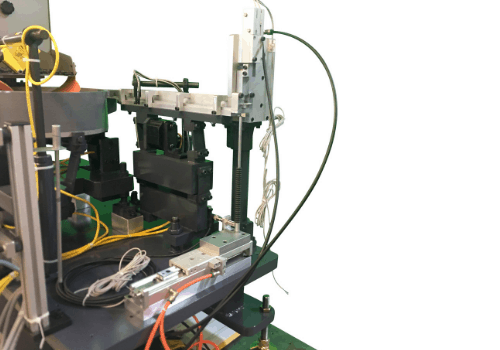

Mechanisms designed to accept parts tracked from Vibromatic part handling systems including centrifugal parts feeders, linear parts feeders, stepper feeders, or vibratory bowl feeders, are offered to provide our customers with complete turnkey solutions.

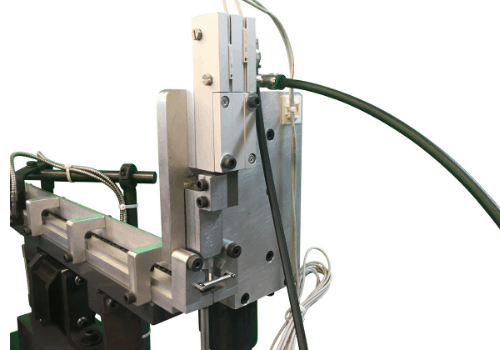

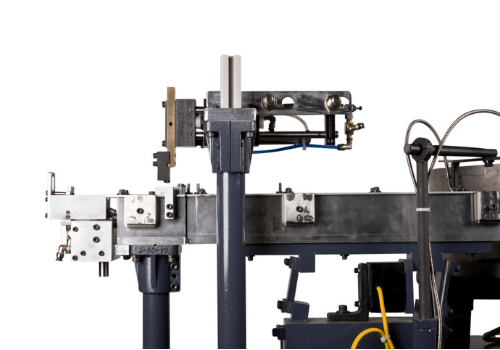

Vibromatic designs and custom builds mechanisms that fit your specific part handling needs. Our product line includes isolator mechanisms, part positioning devices and side shuttle slides that isolate parts for robotic pick and place mechanisms. Before placing your mechanism project into production we submit a scaled concept drawing to assure that it meets your production requirements.

Part Handling Systems, including mechanisms such as side shuttles, and other positioning devices are custom designed to accept your parts after they have been fed from one of our vibratory, centrifugal, floor, or stepper feeders. Since 1956, Vibromatic has been the leader in producing the finest mechanisms to complement our custom tooled Vibratory and Mechanical Parts Feeding and Part Handling Systems. Today, this same drive and dedication to excellence bring our custom tooled mechanisms to fit your part handling system needs.

From the time that you place your order and through the concept and build stages, rest assured that our highly skilled sales engineers, project managers, and builders will work with you to assure that the results will exceed your expectations. Vibromatic part placement and positioning mechanisms are designed using modular components that are readily available for assurance of quality and quick lead times. Vibromatic also carries a vast line of off-the-shelf components to complement our automatic vibratory and mechanical parts feeder systems.

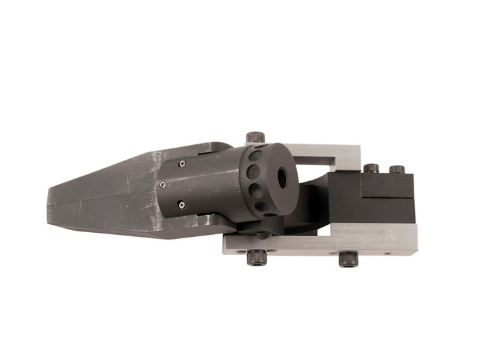

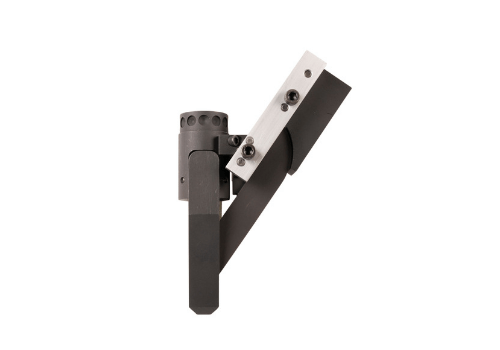

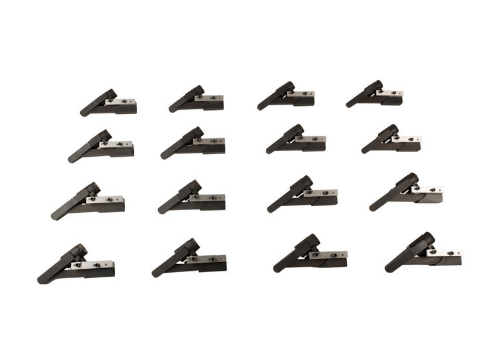

In some cases, where it meets your requirements, we offer standard mechanisms such as our VPI-4 Isolator Mechanism which provided for a low cost yet reliable method of isolating parts.

The VPI (Vibromatic Part Isolator) has been tested under actual operating conditions with over three million cycles and showed only negligible wear. Available as untooled, or tooled, our tooled isolator mechanisms are supplied with proximity switches for cycle detection. This unit offers the flexibility of being mounted in any position, using the main body as a mounting surface. These units are available in standard stroke of 3/4″ vertical and 3-7/8″ horizontal. Additional horizontal and vertical strokes may be quoted on request.

Mechanisms for escapement and placement are custom-designed modular components that will accurately position parts tracked from Vibromatic centrifugal parts feeder, linear parts feeders, stepper feeders, or vibratory bowl feeders, for your automated assembly operation. Standard escapements and isolators are adaptable to your part size and tooling requirements.

Mechanisms for isolation and positioning of your parts tracked from Vibromatic centrifugal parts feeders, linear parts feeders, stepper feeders, or vibratory bowl feeders, provides for a dependable, low cost solution which mechanically escapes parts from centrifugal, linear, or vibratory feeder bowl systems one at a time to a workstation or placement mechanism.

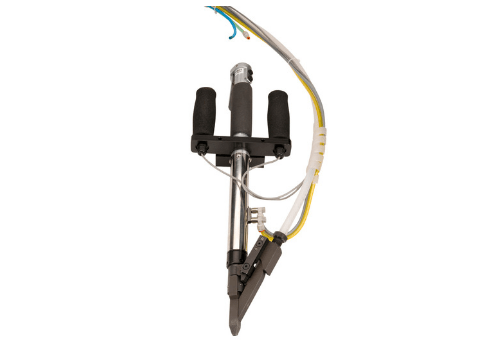

Mechanisms designed for the purpose of escapement of your parts tracked from Vibromatic centrifugal parts feeders, linear parts feeders, stepper feeders, or vibratory feeder bowls, (or bowl feeders), use standard componentry where possible to meet your specific needs. Other examples of customized devices include multitrack escapements, escape and blow devices and single-station assembly mechanisms.

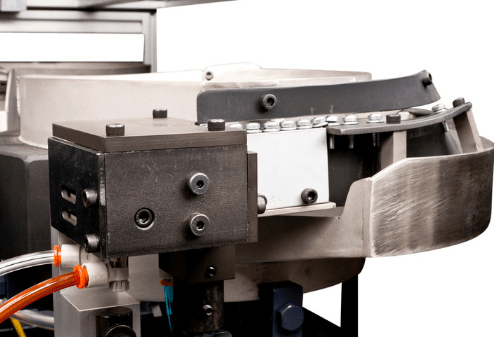

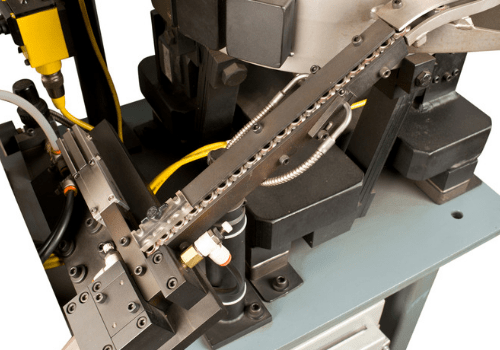

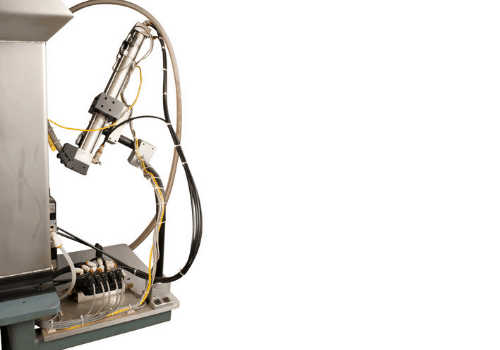

Vibromatic mechanisms include a complete line of escapement mechanisms, including placement and assembly devices designed to accept parts tracked from centrifugal parts feeder bowls, linear parts feeders, stepper feeders, vibratory bowl feeders, and Polycast feeder bowls. (Shown at the right is a standard tooled screw escapement mechanism custom-tooled to accept headed parts from a Polycast feeder bowl and vibratory straight line combination). This concept is most generally used to escape and blow screws to Vibromatic Automatic Screwdrivers.