Controllers for Vibratory Drive Units designed to power automatic vibratory parts feeder bowls.

Designed and developed specifically to provide optimum control and operation of Vibratory Part Handling Systems. These versatile solid-state controls provide the technology to operate Vibratory Drive Units on Bowls, Straight Line Tracks, and Hoppers.

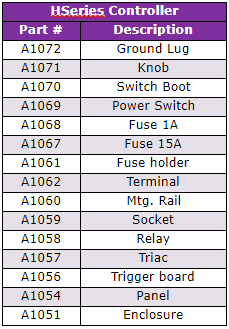

H Series Controllers

Controls are designed with a 25 amp 400 Volt Triac and fused to run loads up to 15 amps continuous power output. The internal circuit is designed to switch loads with low amperage. The “H” series controls have a 3-amp relay for external signals, such as full track switch or level control switch. Output from our controls can be changed from 60 DC pulse to 120 AC pulse operation when operation on 60Hz input. When operating on 50Hz input, the output can be changed from 50 DC pulses to 100 AC pulses. In either case, this change in output frequency can be accomplished by toggling an AC/DC switch located on the Trigger board inside the control box. Any one of the Vibromatic models will control all types of Vibratory Drive Units. The “H” Series controls are mounted in Nema 12 enclosures.

Variable Controllers

Variable frequency regulator is specially designed for maintaining constant feed rates of automatic vibratory parts feeder bowls under various load conditions. The units produce a highly stable output frequency that is adjustable in 0.1 Hz increments. Manual “tuning” the mechanical feed system is significantly reduced. With the sinusoidal output, the feeder runs quietly and ensures gentle product handling. Settings are adjusted by using a touch panel and an integrated digital display. The feed rate set point can be adjusted externally in several ways, including the use of 0…10V or 0(4)…20 mA signals. One set of user parameters can be stored and recalled. The unit is also available with integrated track control and amplitude feedback. Electrical connections are made via input/output power cables.

General Controllers

Controllers for Vibratory Drive Units designed to power automatic vibratory parts feeder bowls, by Vibromatic, were designed and developed specifically to provide optimum control and operation of Vibratory Part Handling Systems.