Vibratory Bulk Supply Hopper Feeders by Vibromatic.

Used when more parts are required than can be stored in parts handling systems including vibratory or centrifugal feeder bowls.

Hopper pre-feeders are available in a variety of sizes and utilize a special tray design that allows for feeding larger parts in greater quantities. As a standard feature, Vibratory Bulk Hopper feeders are signaled to operate through the use of a non-contact level control device. This allows Vibromatic’s vibratory parts handling systems, centrifugal feeder bowls and linear parts feeders to operate efficiently with a constantly metered supply of parts without the costly attention of plant personnel. All Vibromatic vibratory Bulk Hopper Feeders are designed to interface with all types of parts handling and parts feeding systems including vibratory feeder bowls.

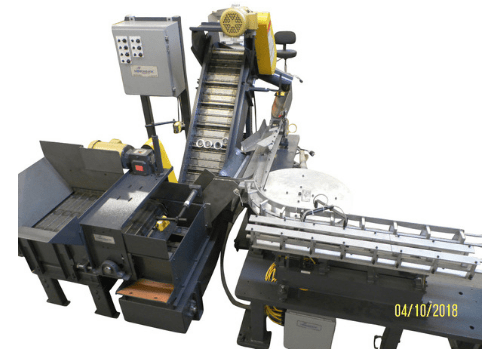

Elevator Hoppers

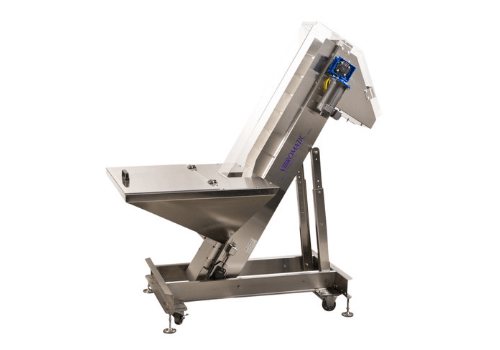

Incline Hoppers

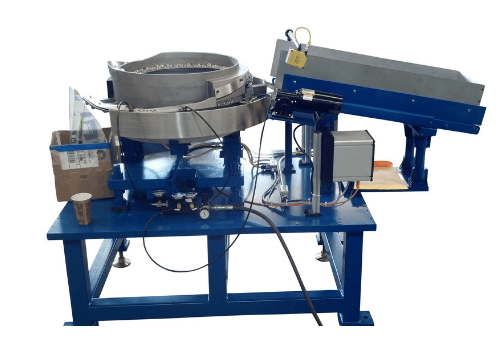

Straight Wall Hoppers